High Pressure Processing Equipment: Powering Food Security, Shelf-Life, and Clean Label Growth in Cold Chain Logistics

High Pressure Processing (HPP) equipment is redefining food safety, shelf-life, and clean-label compliance across cold chains, healthcare, and defense sectors.

NEWARK, DE, UNITED STATES, May 16, 2025 /EINPresswire.com/ -- The High Pressure Processing (HPP) Equipment Market is often viewed through the lens of premium juice production or deli meat sterilization. However, a significantly underexplored yet strategically important dimension is HPP’s role in cold chain logistics, food safety resilience, and the global push for clean-label processed foods. As supply chains extend across continents and consumer awareness about foodborne pathogens continues to rise, HPP is no longer a niche solution—it is becoming a backbone of next-generation food preservation and distribution.

Recent search trends such as HPP in food cold chain, high-pressure preservation vs thermal processing, and clean-label preservation technologies indicate a rising interest among food logistics providers, regulatory agencies, and clean-label product developers. These reflect a broader recognition that HPP is not just a processing technique, but a critical enabler of resilient, traceable, and microbiologically safe global food networks.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-665

𝐓𝐡𝐞 𝐂𝐨𝐥𝐝 𝐂𝐡𝐚𝐢𝐧 𝐀𝐝𝐯𝐚𝐧𝐭𝐚𝐠𝐞: 𝐒𝐭𝐚𝐛𝐢𝐥𝐢𝐳𝐢𝐧𝐠 𝐒𝐚𝐟𝐞𝐭𝐲 𝐖𝐢𝐭𝐡𝐨𝐮𝐭 𝐓𝐡𝐞𝐫𝐦𝐚𝐥 𝐂𝐨𝐦𝐩𝐫𝐨𝐦𝐢𝐬𝐞

In the traditional cold chain, refrigeration slows microbial growth but does not eliminate harmful pathogens or enzymes. This limitation is particularly problematic for fresh or minimally processed products like ready-to-eat meals, seafood, guacamole, and fresh fruit beverages. High Pressure Processing, by contrast, inactivates harmful bacteria such as Listeria, E. coli, and Salmonella without compromising the product’s sensory profile or nutritional content.

In 2023, a logistics study conducted by a European cold chain solutions provider demonstrated that applying HPP to fresh seafood extended its refrigerated shelf life from 6 days to nearly 30 days while preserving flavor and color. This shelf-life extension enabled longer-distance shipping from Norway to Singapore without the need for deep freezing, significantly reducing energy consumption and improving texture retention.

By integrating HPP units into distribution hubs or production facilities near ports, companies are creating hybrid cold chains that combine microbial stability with flexible transport windows. This approach is being adopted by high-end retailers and airlines, especially in Europe and Asia, who seek to offer fresh, safe, and preservative-free food across long distances.

𝐂𝐥𝐞𝐚𝐧 𝐋𝐚𝐛𝐞𝐥 𝐃𝐞𝐦𝐚𝐧𝐝: 𝐇𝐏𝐏 𝐚𝐬 𝐚 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲 𝐟𝐨𝐫 𝐀𝐝𝐝𝐢𝐭𝐢𝐯𝐞-𝐅𝐫𝐞𝐞 𝐀𝐬𝐬𝐮𝐫𝐚𝐧𝐜𝐞

The rise of the clean-label movement has reshaped the food processing industry, with consumers increasingly rejecting artificial preservatives, chemical additives, and unrecognizable ingredients. While thermal and chemical preservation methods often alter food structure or require additional stabilizers, HPP offers a non-thermal, non-chemical pathway to safety and longevity.

In the United States, nearly 64% of consumers consider “no artificial preservatives” a priority when purchasing packaged food, according to a 2024 survey by the Clean Label Project. HPP allows brands to meet this demand by enabling natural preservation without compromising on safety. Products like cold-pressed juices, hummus, and sliced meats processed through HPP are able to carry “clean label” designations while achieving regulatory compliance.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/high-pressure-processing-market

A 2022 case study from a California-based baby food startup showed how implementing HPP extended the shelf life of their refrigerated fruit blends from 15 days to 90 days without the use of citric acid or ascorbic preservatives. This allowed for broader distribution while maintaining compliance with organic and clean-label certification standards.

As consumer demand grows for ingredient transparency, food producers are increasingly choosing HPP over traditional methods. This makes HPP equipment not just a technological investment, but a strategic marketing enabler in the premium food segment.

𝐅𝐨𝐨𝐝 𝐒𝐞𝐜𝐮𝐫𝐢𝐭𝐲 𝐚𝐧𝐝 𝐁𝐢𝐨𝐫𝐞𝐬𝐢𝐥𝐢𝐞𝐧𝐜𝐞: 𝐀 𝐑𝐨𝐥𝐞 𝐢𝐧 𝐄𝐦𝐞𝐫𝐠𝐞𝐧𝐜𝐲 𝐚𝐧𝐝 𝐃𝐞𝐟𝐞𝐧𝐬𝐞 𝐒𝐮𝐩𝐩𝐥𝐲 𝐂𝐡𝐚𝐢𝐧𝐬

Beyond retail and convenience, HPP’s role in food security and national resilience strategies is gaining attention. Government agencies and defense departments are exploring HPP for emergency meal kits, military rations, and disaster relief food packs, where shelf stability, pathogen control, and quality retention are vital.

During the COVID-19 pandemic, several food banks in Canada and the U.S. turned to HPP to safely extend the usability of perishable donations such as dairy, dips, and soups. In 2024, the U.S. Department of Defense began piloting HPP-packaged, refrigerated meal kits for naval deployment, citing the method’s ability to eliminate pathogens while preserving nutritional integrity over long storage periods.

This positioning of HPP as a critical infrastructure tool in national food reserves and disaster preparedness plans adds a new layer of value beyond commercial food service or retail. It also opens up a high-value niche for equipment providers to target public sector and defense procurement pipelines.

𝐑𝐞𝐠𝐢𝐨𝐧𝐚𝐥 𝐓𝐫𝐞𝐧𝐝𝐬 𝐚𝐧𝐝 𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐲 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐦𝐞𝐧𝐭𝐬

While North America currently leads in HPP equipment installations, accounting for over 45% of global volume in 2024, Asia-Pacific is witnessing the fastest growth. The rapid expansion of premium retail chains and e-commerce food delivery in markets like China, Japan, and South Korea is driving investment in compact and modular HPP units designed for small to mid-size food businesses.

In Europe, regulatory support is pushing food companies to reduce chemical preservatives, leading to a surge in HPP adoption in countries like France, Germany, and the Netherlands. Meanwhile, Latin America is emerging as a strategic market, especially for exporters of tropical fruit-based beverages and avocado products, where HPP enhances safety for U.S. and European import compliance.

Technologically, the market is seeing advances in continuous HPP systems, which overcome traditional batch-processing bottlenecks. In 2023, a Spanish engineering firm unveiled an inline HPP prototype capable of processing up to 10,000 liters per hour, paving the way for mass-market scalability.

𝐇𝐞𝐚𝐯𝐲 𝐄𝐧𝐠𝐢𝐧𝐞𝐞𝐫𝐢𝐧𝐠 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/heavy-engineering-solutions

𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐮𝐭𝐥𝐨𝐨𝐤: 𝐑𝐞𝐬𝐢𝐥𝐢𝐞𝐧𝐭 𝐆𝐫𝐨𝐰𝐭𝐡 𝐰𝐢𝐭𝐡 𝐃𝐢𝐯𝐞𝐫𝐬𝐢𝐟𝐢𝐞𝐝 𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬

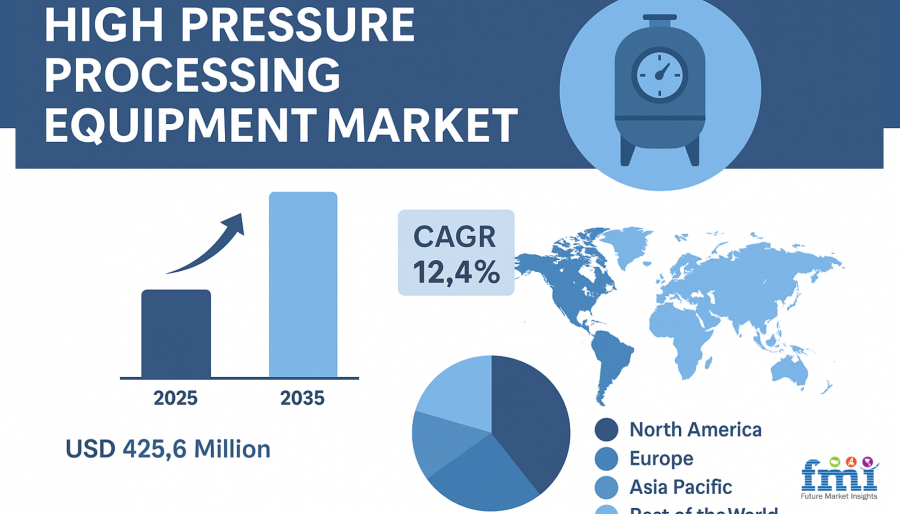

The High Pressure Processing Equipment market is estimated to reach USD 425.6 million by 2025, and AVG around USD 1.4 billion by 2035, at a CAGR of 12.4% during the forecast period. While core demand remains anchored in juice, deli meats, and avocado products, the growing relevance of HPP in logistics, clean label manufacturing, and government resilience planning is opening up new, high-impact segments.

Major players are no longer competing solely on throughput or price—they are differentiating through customizable systems, automation capabilities, and energy-efficient designs. As HPP becomes more integrated into digital food processing ecosystems, its role will expand from a pathogen control measure to a platform technology for modern food resilience.

𝐊𝐞𝐲 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐬 𝐨𝐟 𝐇𝐢𝐠𝐡 𝐏𝐫𝐞𝐬𝐬𝐮𝐫𝐞 𝐏𝐫𝐨𝐜𝐞𝐬𝐬𝐢𝐧𝐠 𝐄𝐪𝐮𝐢𝐩𝐦𝐞𝐧𝐭 𝐌𝐚𝐫𝐤𝐞𝐭

By Application:

- Fruits & Vegetables

- Juice & Beverages

- Meat

- Seafood

- Other

By Product Type:

- Below 100 Liters

- 100 Litres- 300 Liters

- Above 300 Liters

By Vessel Arrangement:

- Vertical

- Horizontal

By Region:

- North America

- Latin America

- Western Europe

- Eastern Europe

- East Asia

- South Asia Pacific

- Middle East and Africa

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Ethoxylates Market: https://www.futuremarketinsights.com/reports/ethoxylates-market

USA and Canada Copper Market: https://www.futuremarketinsights.com/reports/usa-and-canada-copper-market

Europe Fine Chemical Market: https://www.futuremarketinsights.com/reports/europe-fine-chemical-market

Qatar Cement Market: https://www.futuremarketinsights.com/reports/qatar-cement-market

Porous Ceramic Market: https://www.futuremarketinsights.com/reports/porous-ceramic-market

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release